Life Cycle Analysis Heat pump Gas / fuel boiler alternative Direct Product Solution  Envision a future where our cities are healthier, and the energy we use to heat and cool our homes is sustainable and efficient. This technology represents more than just a product; it is a decisive step towards that future. Designed to challenge the dominance of natural gas in urban areas, this solution offers a transformative approach to reducing carbon emissions on a large scale. Our mission is to make zero-carbon heating and cooling the standard, not the exception. By deploying heat pumps at an unprecedented scale, we are pioneering a more efficient and resilient energy system—one that minimizes energy transmission losses, harnesses waste heat, and empowers cities to adopt sustainable living practices. This initiative is about enabling urban areas, regardless of density, to transition to cleaner, smarter energy solutions, actively contributing to the EU’s Net Zero goals. As we advance this technology, we are collaborating with ClimatePoint to refine and expand our impact strategy. This partnership is helping us gain deeper insights into various global markets, positioning us as leaders in climate solutions and establishing our role as a data-driven differentiator in the market. Index

Analysis ParametersGoal and scopeFunctional UnitUnit of heat pump The functional unit for this analysis is a single heat pump unit produced by the company. This unit encompasses all material and service inputs required for production, as well as emissions associated with its operational phase. The heat pump is benchmarked against a conventional natural gas boiler, the primary technology it is designed to replace. This comparison addresses raw material inputs, transport to customers, and operational emissions, providing a comprehensive assessment of the heat pump's environmental performance relative to fossil fuel-based alternatives. BenchmarkAvoided heating by Natural Gas This avoided impact profile highlights the emissions avoided by replacing natural gas boilers with heat pumps, focusing on both the production and operational phases of natural gas heating systems. By adopting heat pumps, the substantial emissions associated with the manufacturing of natural gas boilers, including raw material extraction and energy-intensive production processes, are effectively eliminated. Furthermore, the operational emissions from burning natural gas for heating, a significant source of greenhouse gases, are also avoided. Additionally, potential improvements in transportation logistics, compared to the distribution of gas boilers, further amplify the environmental benefits of switching to heat pumps. Avoided heating by Fuel Oil This avoided impact profile demonstrates the emissions avoided by substituting fuel oil boilers with heat pumps, addressing both the production and use phases of fuel oil heating systems. Transitioning to heat pumps eliminates the considerable emissions linked to the manufacturing of fuel oil boilers, as well as the carbon-intensive process of burning fuel oil for heat. Moreover, improvements in transportation logistics, particularly when compared to the delivery and distribution of fuel oil and boilers, enhance the environmental advantages of heat pumps over traditional fuel oil systems. Reference flowThe heat pump's annual energy consumption is estimated at 2,666 kWh/year, equivalent to approximately 9,096,392 BTU/year. This energy use serves as a basis for evaluating the environmental impacts throughout the heat pump's lifecycle. GoalThe objective of this climate LCA is to quantify the environmental impacts associated with one heat pump unit, from cradle to grave, including production, use, and disposal phases. The analysis aims to identify key impact areas within the value chain, enabling the identification of carbon emission hotspots and providing insights for potential improvements in sustainability. Reason for studyThe study is intended to inform decision-making processes by identifying carbon emission hotspots throughout the heat pump's lifecycle. The findings will guide the production company in focusing on areas with the greatest potential for decarbonization, ultimately enhancing the environmental performance of their products. AudienceThe primary audience for this climate LCA includes the production company and its strategic stakeholders, such as impact investors and key clients. The insights gained from this analysis will be crucial for aligning business strategies with sustainability goals. ScopeSystem BoundaryThis assessment covers the entire lifecycle of the heat pump, from raw material extraction to end-of-life disposal, encompassing production, transportation, and operational use. The analysis considers direct, indirect, and induced emissions, with a particular focus on Scope 2 and Scope 3 emissions associated with the heat pump. LifetimeThe heat pump is designed for a lifespan of over 15 years, with the potential for extension through the replacement of certain components. At the end of its life, the refrigerant must be safely removed, and the unit can be dismantled, sorted, and recycled to minimize environmental impact. MethodologyMeeting international standardsThis analysis adheres to Lifecycle Assessment (LCA) methodologies outlined in ISO 14040, 14044, and 14067, ensuring a structured approach, potential comparability between solutions, and transparency for readers. The report is based on data available during the study and within the agreed scope. Results reflect the best available data and methodologies, with accuracy and reliability dependent on data quality and completeness at the time of the study. Limitations or uncertainties in the data are explicitly stated. The data used is precise (considering uncertainties and variability), complete (capturing all inflows and outflows within system boundaries), representative (aligned with geography, time, and technology), and consistent. It should be noted that LCA results depend on system boundaries, allocation methods, data quality, and assumptions; where deviations may affect outcomes. ClimatePoint impact analysts herein apply professional judgment and relevant standards while maintaining client confidentiality. Data QualityTechnology coverageThe analysis is based on the most up-to-date technological data, utilizing emission factors from the latest version of the Ecoinvent database. This ensures that the assessment reflects the best available technology and its environmental impact. Temporal coverageThe climate LCA utilizes the most recent data available from the Ecoinvent database, deemed representative for the time period covered by the report. To maintain accuracy and relevance, periodic updates to the assessment will be necessary as new data becomes available. Geographical boundaryThe geographical scope of this climate LCA spans Europe and Asia, reflecting the regions from which raw materials are sourced and where the heat pumps are manufactured. The energy consumption analysis is based on the EU electricity mix, aligning with the regions where the heat pumps are primarily deployed. Assumptions and limitationsCertain aspects of the lifecycle, such as end-of-life recycling, refrigerant replacement, water emissions, and waste stream management, are discussed qualitatively but not quantitatively analyzed in this report. These areas may offer potential for future emission reductions and could be evaluated in subsequent assessments. Functional UnitUnit of heat pump Executive SummaryKey revelationsThe analysis has uncovered several critical insights regarding the environmental and operational impact of heat pumps:

Insights to Impact StrategyKey factors highlight the most effective strategies for maximizing the impact of heat pump technology:

Potential ChallengesSeveral key factors could influence the overall effectiveness and sustainability of heat pump technology:

Possible ReboundsWhile heat pumps offer substantial benefits, several potential rebound effects could diminish their overall impact:

Climate Value PropositionKey elements that define the climate value of heat pump technology:

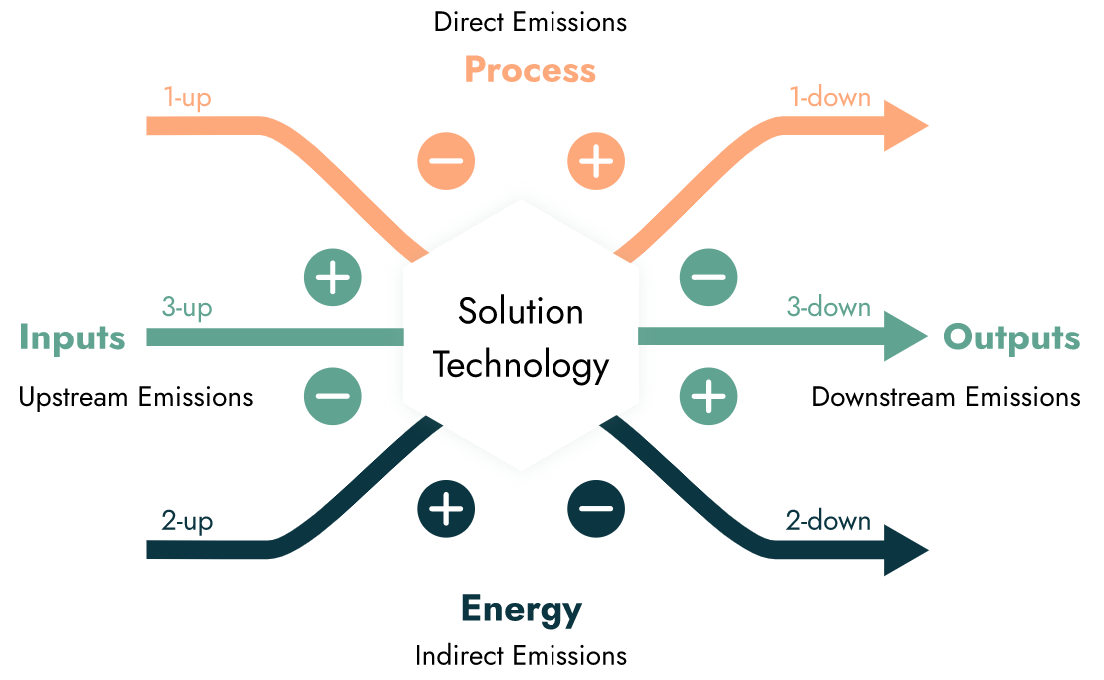

Life Cycle OverviewUnderstanding your emission profileThis process summary depicts an overview of the most significant emission factors that take place throughout your lifecycle activity. By viewing these intensities alongside each other, you can gauge their relative importance with respect to positive and negative extremes. Each process item listed on the horizontal axis will be described further in the Scope Allocation Analysis where readers can dive into the details behind each of the data points. While this model represents the complete overview, we make sure that each factor is supported by a sound methodology. Building your impact foundationSome process items may remain blank because the ClimatePoint team has considered them to be out of project scope, insignificant, or without enough information to analyse. These gaps should eventually be completed as you aim for your emission profile to approach higher levels of accuracy. Because of this presentation, you can understand which additional data is necessary to complete your entire impact profile and accommodate the dynamic growth and scalability of your company. ClimatePoint is here to help you navigate this pathway and optimize your impact strategy. Benchmark: Avoided heating by Natural GasImpact Category: Climate change Benchmark: Avoided heating by Fuel OilImpact Category: Climate change Process Overview Connecting academia with businessThe scope allocation analysis is the ClimatePoint strategy to bridge the LCA emission assessment to the world of corporate GHG reporting. When our team approaches a new technology, we start with the most significant aspects that outline both your generated emissions and your avoided emission impact. The following process items represent these key factors backed by a defined methodology approach. This format permits the technology to be strategically aligned with our global climate targets, challenged for verification, and refined with evolution and growth. As the climate solution matures, we can easily update or add process items making this a truly dynamic report. This ClimatePoint approach integrates impact foundations outlined by the international community. To help you interpret the key climate aspects of your technology, we assign each process item two labels to serve as high level indicators. Your most significant climate impactThe "Score" evaluates processes based on comparative impact: Aligned signifies measurable emission reductions compared to the benchmark; Potential suggests possible alignment pending further verification; Negative denotes additional emissions; Rebound identifies emissions that would have otherwise not occurred with the benchmark; and None represents qualitative assessments. The "Priority" label ranks processes by importance: High indicates critical processes essential for achieving key sustainability objectives, warranting immediate attention; Medium represents processes contributing to the impact profile that require attention but lack urgency; and Low applies to supplementary processes with less immediate impact or those already aligned, allowing deferred action until higher-priority tasks are addressed. # Process item Scope Score Priority Impact AnalysisFunctional unit profileThis graph represents the aggregation of all the aforementioned emission factors with respect to the defined functional unit. By selecting a benchmark, the corresponding avoided emissions will also be displayed on the graph. This enables you to see the difference in the emission profile that this climate solution has to the incumbent technology. There is also an effect filter to identify which impact factors only occur once and which recur multiple times, usually throughout the lifetime use of the product or service. You can click the process labels in the legend to hide and show different elements to reveal further insights.

ProjectionsHow to read this section

Scenario 1: Aggregated Projections (Planned Impact)This scenario outlines the company’s anticipated growth and market impact, focusing on production and market metrics.

Benchmark 1: Avoided heating by Natural GasThis avoided impact profile highlights the emissions avoided by replacing natural gas boilers with heat pumps, focusing on both the production and operational phases of natural gas heating systems. By adopting heat pumps, the substantial emissions associated with the manufacturing of natural gas boilers, including raw material extraction and energy-intensive production processes, are effectively eliminated. Furthermore, the operational emissions from burning natural gas for heating, a significant source of greenhouse gases, are also avoided. Additionally, potential improvements in transportation logistics, compared to the distribution of gas boilers, further amplify the environmental benefits of switching to heat pumps. Scenario 1: Aggregated Projections (Planned Impact)This scenario outlines the company’s anticipated growth and market impact, focusing on production and market metrics.

Benchmark 2: Avoided heating by Fuel OilThis avoided impact profile demonstrates the emissions avoided by substituting fuel oil boilers with heat pumps, addressing both the production and use phases of fuel oil heating systems. Transitioning to heat pumps eliminates the considerable emissions linked to the manufacturing of fuel oil boilers, as well as the carbon-intensive process of burning fuel oil for heat. Moreover, improvements in transportation logistics, particularly when compared to the delivery and distribution of fuel oil and boilers, enhance the environmental advantages of heat pumps over traditional fuel oil systems. Scenario 2: Single unit impact (produced 2023; installed 2024)This scenario models the impact of one heat pump produced in 2023 and installed in 2024, with projections extending over 10 years, though the unit's lifespan is expected to be longer.

Benchmark 1: Avoided heating by Natural GasThis avoided impact profile highlights the emissions avoided by replacing natural gas boilers with heat pumps, focusing on both the production and operational phases of natural gas heating systems. By adopting heat pumps, the substantial emissions associated with the manufacturing of natural gas boilers, including raw material extraction and energy-intensive production processes, are effectively eliminated. Furthermore, the operational emissions from burning natural gas for heating, a significant source of greenhouse gases, are also avoided. Additionally, potential improvements in transportation logistics, compared to the distribution of gas boilers, further amplify the environmental benefits of switching to heat pumps. Scenario 2: Single unit impact (produced 2023; installed 2024)This scenario models the impact of one heat pump produced in 2023 and installed in 2024, with projections extending over 10 years, though the unit's lifespan is expected to be longer.

Benchmark 2: Avoided heating by Fuel OilThis avoided impact profile demonstrates the emissions avoided by substituting fuel oil boilers with heat pumps, addressing both the production and use phases of fuel oil heating systems. Transitioning to heat pumps eliminates the considerable emissions linked to the manufacturing of fuel oil boilers, as well as the carbon-intensive process of burning fuel oil for heat. Moreover, improvements in transportation logistics, particularly when compared to the delivery and distribution of fuel oil and boilers, enhance the environmental advantages of heat pumps over traditional fuel oil systems. Scenario 3: 100 unit impact (produced 2023; installed 2024)This scenario models the impact of 100 heat pumps produced and installed in 2024, with projections extending over 10 years, although the lifespan of each unit is expected to be longer.

Benchmark 1: Avoided heating by Natural GasThis avoided impact profile highlights the emissions avoided by replacing natural gas boilers with heat pumps, focusing on both the production and operational phases of natural gas heating systems. By adopting heat pumps, the substantial emissions associated with the manufacturing of natural gas boilers, including raw material extraction and energy-intensive production processes, are effectively eliminated. Furthermore, the operational emissions from burning natural gas for heating, a significant source of greenhouse gases, are also avoided. Additionally, potential improvements in transportation logistics, compared to the distribution of gas boilers, further amplify the environmental benefits of switching to heat pumps. Scenario 3: 100 unit impact (produced 2023; installed 2024)This scenario models the impact of 100 heat pumps produced and installed in 2024, with projections extending over 10 years, although the lifespan of each unit is expected to be longer.

Benchmark 2: Avoided heating by Fuel OilThis avoided impact profile demonstrates the emissions avoided by substituting fuel oil boilers with heat pumps, addressing both the production and use phases of fuel oil heating systems. Transitioning to heat pumps eliminates the considerable emissions linked to the manufacturing of fuel oil boilers, as well as the carbon-intensive process of burning fuel oil for heat. Moreover, improvements in transportation logistics, particularly when compared to the delivery and distribution of fuel oil and boilers, enhance the environmental advantages of heat pumps over traditional fuel oil systems. Scenario 4: 1,000 unit impact (produced 2023; installed 2024)This scenario models the impact of 1,000 heat pumps produced and installed in 2024, with projections extending over 10 years, although the lifespan of each unit is expected to be longer.

Benchmark 1: Avoided heating by Natural GasThis avoided impact profile highlights the emissions avoided by replacing natural gas boilers with heat pumps, focusing on both the production and operational phases of natural gas heating systems. By adopting heat pumps, the substantial emissions associated with the manufacturing of natural gas boilers, including raw material extraction and energy-intensive production processes, are effectively eliminated. Furthermore, the operational emissions from burning natural gas for heating, a significant source of greenhouse gases, are also avoided. Additionally, potential improvements in transportation logistics, compared to the distribution of gas boilers, further amplify the environmental benefits of switching to heat pumps. Scenario 4: 1,000 unit impact (produced 2023; installed 2024)This scenario models the impact of 1,000 heat pumps produced and installed in 2024, with projections extending over 10 years, although the lifespan of each unit is expected to be longer.

Benchmark 2: Avoided heating by Fuel OilThis avoided impact profile demonstrates the emissions avoided by substituting fuel oil boilers with heat pumps, addressing both the production and use phases of fuel oil heating systems. Transitioning to heat pumps eliminates the considerable emissions linked to the manufacturing of fuel oil boilers, as well as the carbon-intensive process of burning fuel oil for heat. Moreover, improvements in transportation logistics, particularly when compared to the delivery and distribution of fuel oil and boilers, enhance the environmental advantages of heat pumps over traditional fuel oil systems. Scenario 5: Potential Impact: World Market IEA (until 2030)This scenario projects the global market impact of heat pumps until 2030, based on the International Energy Agency’s "Net Zero by 2050" report.

Benchmark 1: Avoided heating by Natural GasThis avoided impact profile highlights the emissions avoided by replacing natural gas boilers with heat pumps, focusing on both the production and operational phases of natural gas heating systems. By adopting heat pumps, the substantial emissions associated with the manufacturing of natural gas boilers, including raw material extraction and energy-intensive production processes, are effectively eliminated. Furthermore, the operational emissions from burning natural gas for heating, a significant source of greenhouse gases, are also avoided. Additionally, potential improvements in transportation logistics, compared to the distribution of gas boilers, further amplify the environmental benefits of switching to heat pumps. Scenario 5: Potential Impact: World Market IEA (until 2030)This scenario projects the global market impact of heat pumps until 2030, based on the International Energy Agency’s "Net Zero by 2050" report.

Benchmark 2: Avoided heating by Fuel OilThis avoided impact profile demonstrates the emissions avoided by substituting fuel oil boilers with heat pumps, addressing both the production and use phases of fuel oil heating systems. Transitioning to heat pumps eliminates the considerable emissions linked to the manufacturing of fuel oil boilers, as well as the carbon-intensive process of burning fuel oil for heat. Moreover, improvements in transportation logistics, particularly when compared to the delivery and distribution of fuel oil and boilers, enhance the environmental advantages of heat pumps over traditional fuel oil systems. Scenario 6: Potential Impact: World Market IEA (until 2050)This scenario projects the global market impact of heat pumps through 2050, based on the International Energy Agency’s "Net Zero by 2050" report.

Benchmark 1: Avoided heating by Natural GasThis avoided impact profile highlights the emissions avoided by replacing natural gas boilers with heat pumps, focusing on both the production and operational phases of natural gas heating systems. By adopting heat pumps, the substantial emissions associated with the manufacturing of natural gas boilers, including raw material extraction and energy-intensive production processes, are effectively eliminated. Furthermore, the operational emissions from burning natural gas for heating, a significant source of greenhouse gases, are also avoided. Additionally, potential improvements in transportation logistics, compared to the distribution of gas boilers, further amplify the environmental benefits of switching to heat pumps. Scenario 6: Potential Impact: World Market IEA (until 2050)This scenario projects the global market impact of heat pumps through 2050, based on the International Energy Agency’s "Net Zero by 2050" report.

Benchmark 2: Avoided heating by Fuel OilThis avoided impact profile demonstrates the emissions avoided by substituting fuel oil boilers with heat pumps, addressing both the production and use phases of fuel oil heating systems. Transitioning to heat pumps eliminates the considerable emissions linked to the manufacturing of fuel oil boilers, as well as the carbon-intensive process of burning fuel oil for heat. Moreover, improvements in transportation logistics, particularly when compared to the delivery and distribution of fuel oil and boilers, enhance the environmental advantages of heat pumps over traditional fuel oil systems. |

ClimatePoint Funding the Future ClimatePoint AS Universitetsgata 12, 0157 Oslo |

ClimatePoint AS, Universitetsgata 12, 0157 Oslo Follow us on X | Follow us on LinkedIn |