Life Cycle Analysis Protein ingredient (Public) Alternative for animal analogs Direct Product Solution  NOSH's protein, derived from non-GMO fungi, is designed for various food applications, offering a sustainable and nutritious alternative to traditional and other plant-based proteins. Its versatility allows it to be used in meat, seafood, dairy analogues, sauces, and pet food, providing a clean label, single-ingredient solution. The protein is rich in fiber and essential nutrients, catering to the growing demand for healthy and environmentally friendly food options. NOSH emphasizes minimal processing to retain the natural goodness of their product, aligning with consumer preferences for less processed foods. This innovative approach supports sustainability and circular economy principles, aiming to significantly reduce environmental impact. This impact analysis is specific to NOSH's alternative protein that is currently. It covers protein production through various stages, systematically evaluates environmental impacts from raw material sourcing to end-of-life, including avoided production from alternatives, land use changes, cutting and packaging, cold storage at 4.5 degrees, transportation to customers, storage at the customer using electricity, packaging waste, and disposal or recycling. Recommendations may focus on reducing carbon footprint, improving energy efficiency, optimizing logistics, and enhancing packaging sustainability. The report aims to inform stakeholders of the environmental performance and guide decision-making towards more sustainable practices. Index

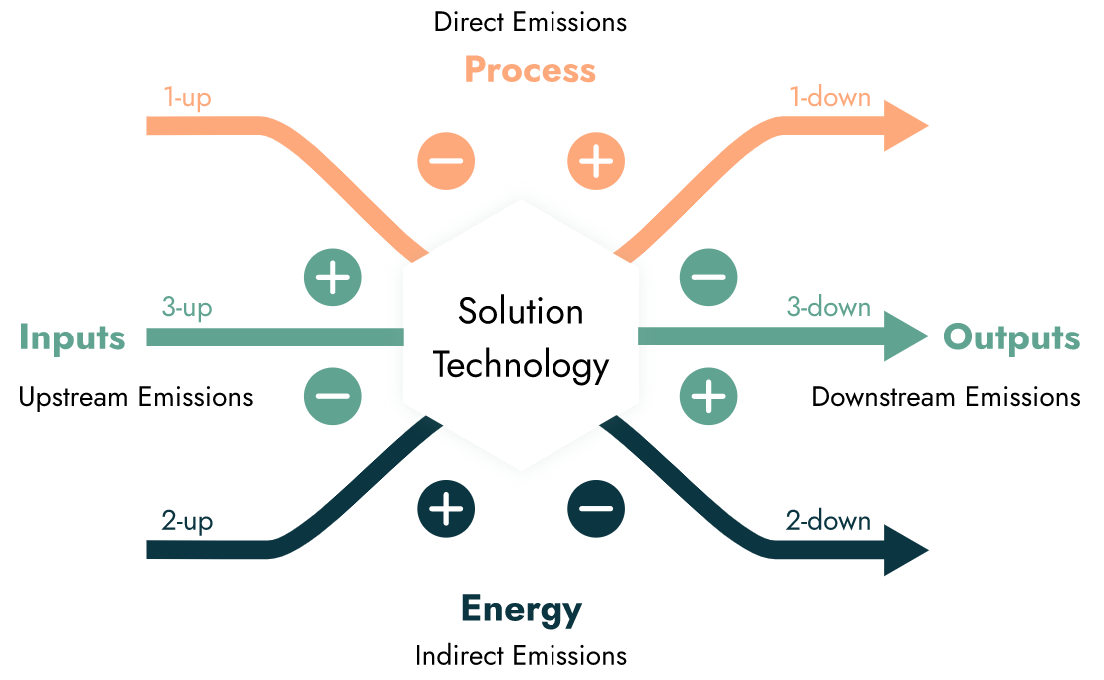

Analysis ParametersGoal and scopeFunctional UnitKg of protein ingredient (Public) The functional unit of this report is the market use of one kilogram of Nosh's protein (in wet mass). BenchmarkConventional beef (per weight comparison) The main benchmark of this report is the production of conventional beef. It is compared on a 1:1 weight basis to NOSH's protein. The benchmark considers the lifecycle of beef production cradle-to-gate, however excludes farm building emissions due to the lack of reliable data. This benchmark is compared to the alternative protein of Nosh, revealing the differences in environmental impacts. Conventional beef (protein content comparison) This benchmark compares the emissions of NOSH's product on a protein content basis. As the company's product has 1/3 of the protein of conventional beef, around 3 times the amount of NOSH's product is required for the same amount of protein. Reference flowThe reference flow(s) for the use of Nosh's alternative protein is one kilogram of beef protein. GoalThe goal of the LCA is to estimate the environmental impacts associated with 1 kg of final product, conducting a gate-to-grave analysis and a hotspot identification; thus, not only to calculate the impacts but to analyze where the main impacts are coming from in the value chain. Reason for studyThe findings from this study will aid decision-making. By highlighting carbon emission hotspots, NOSH can concentrate its efforts on them to decarbonize the value chain of its solution. AudienceThe intended audience of this study is NOSH and its strategic stakeholders, including impact investors and key clients. ScopeSystem BoundaryThe system boundary includes the downstream processes of the wet mass protein production, thus the market activity. These processes include the cold storage of the protein before being transported to the customer, until its end-of-life, meaning leftovers that are thrown away. LifetimeNon-Disclosure. MethodologyMeeting international standardsThis analysis adheres to Lifecycle Assessment (LCA) methodologies outlined in ISO 14040, 14044, and 14067, ensuring a structured approach, potential comparability between solutions, and transparency for readers. The report is based on data available during the study and within the agreed scope. Results reflect the best available data and methodologies, with accuracy and reliability dependent on data quality and completeness at the time of the study. Limitations or uncertainties in the data are explicitly stated. The data used is precise (considering uncertainties and variability), complete (capturing all inflows and outflows within system boundaries), representative (aligned with geography, time, and technology), and consistent. It should be noted that LCA results depend on system boundaries, allocation methods, data quality, and assumptions; where deviations may affect outcomes. ClimatePoint impact analysts herein apply professional judgment and relevant standards while maintaining client confidentiality. Data QualityTechnology coverageThe various data points take into account the best available technology information based on emission factors primarily sourced from the most recent version of the Ecoinvent database. Temporal coverageThis data is assumed to be representative and valid for the entire duration of the production projections covered in this report. Regular updates to the LCA may be necessary to ensure its continued accuracy and relevance. Geographical boundaryThe data has been collected for Germany, Poland and Italy, which is the country/area/region where the raw materials are being source from and the production plant is located. The client(s) are located in Germany, for this the amount of kilometers from the production plant to the client location is accounted. Assumptions and limitationsThis report only models the emissions from the market use of the protein and not its production. This is done in a separate report that is built into this report. Functional UnitKg of protein ingredient (Public) Executive SummaryKey revelationsProtein production is the largest source of emissions in the company's emissions profile. A cleaner energy mix, or renewable energies should be used to lower the emissions from the production. Additionally, infrastructure emissions from the new facility in Germany should be considered in the future. Land use change is another important discussion point. As NOSH's product requires less land than beef per kg of product, it should be discussed how this advantage can be used to mitigate the company's crbon impacts, through reforestation measures. Insights to Impact StrategyNOSH's impact strategy is centered around sustainable innovation in the food industry. The company aims to develop superior functional ingredients and nutritional proteins by leveraging microbial biodiversity and novel fermentation technologies. Their focus on clean label, non-GMO products at industry cost levels reflects a commitment to environmental sustainability and health. This approach not only addresses the growing demand for alternative proteins but also aligns with global efforts to reduce the environmental footprint of food production. Potential ChallengesPotential challenges for NOSH could include technical hurdles in optimizing fermentation processes for scale, ensuring the functional and nutritional qualities of their plant-based proteins match or exceed those of animal-derived counterparts, and the economic challenge of achieving cost-competitiveness with traditional food sources. Additionally, NOSH faces climate challenges in scaling up its sustainable protein production, including optimizing energy use in fermentation processes, managing water resources efficiently, and minimizing waste generation. Balancing the environmental impact of raw material sourcing, especially non-GMO fungi, poses another challenge, as does ensuring the overall lifecycle of the product contributes positively to climate goals. Furthermore, transitioning to renewable energy sources for production facilities and addressing transportation emissions are critical for reducing the carbon footprint. Collaborating with stakeholders to improve sustainability in the supply chain and investing in innovations that reduce environmental impact are essential strategies for NOSH to overcome these challenges. Possible ReboundsThe production of NOSH's alternative protein could introduce rebound effects, where increased efficiency and affordability lead to higher consumption rates, potentially negating some environmental benefits. This phenomenon suggests that more accessible alternative proteins might not always result in decreased demand for traditional animal proteins, but instead could expand total protein consumption. The environmental savings from reduced meat production could be offset by the resources required for scaling up alternative protein production. Additionally, if not managed sustainably, the energy and inputs for producing fungi-based proteins could introduce new environmental pressures. Mitigating these effects requires careful consideration of production methods, energy sources, and consumer behavior to ensure that the shift towards alternative proteins contributes positively to sustainability goals. Policymakers and companies must work together to develop strategies that encourage responsible consumption and support the sustainable growth of the alternative protein sector. Climate Value PropositionNOSH's climate value proposition likely involves leveraging sustainable production methods to minimize environmental impact, focusing on reducing carbon emissions, conserving water, and promoting biodiversity through the use of alternative, plant-based proteins. This approach not only aims to offer eco-friendly food solutions but also addresses the broader challenge of climate change by providing more sustainable food options. The main effects occur mostly as downstream scope 3 effects, as this report models the emissions of the protein after its production. Life Cycle OverviewUnderstanding your emission profileThis process summary depicts an overview of the most significant emission factors that take place throughout your lifecycle activity. By viewing these intensities alongside each other, you can gauge their relative importance with respect to positive and negative extremes. Each process item listed on the horizontal axis will be described further in the Scope Allocation Analysis where readers can dive into the details behind each of the data points. While this model represents the complete overview, we make sure that each factor is supported by a sound methodology. Building your impact foundationSome process items may remain blank because the ClimatePoint team has considered them to be out of project scope, insignificant, or without enough information to analyse. These gaps should eventually be completed as you aim for your emission profile to approach higher levels of accuracy. Because of this presentation, you can understand which additional data is necessary to complete your entire impact profile and accommodate the dynamic growth and scalability of your company. ClimatePoint is here to help you navigate this pathway and optimize your impact strategy. Benchmark: Conventional beef (per weight comparison)Impact Category: Climate change Impact Category: Land use Impact Category: Water deprivation potential Benchmark: Conventional beef (protein content comparison)Impact Category: Climate change Impact Category: Land use Impact Category: Water deprivation potential Process Overview Connecting academia with businessThe scope allocation analysis is the ClimatePoint strategy to bridge the LCA emission assessment to the world of corporate GHG reporting. When our team approaches a new technology, we start with the most significant aspects that outline both your generated emissions and your avoided emission impact. The following process items represent these key factors backed by a defined methodology approach. This format permits the technology to be strategically aligned with our global climate targets, challenged for verification, and refined with evolution and growth. As the climate solution matures, we can easily update or add process items making this a truly dynamic report. This ClimatePoint approach integrates impact foundations outlined by the international community. To help you interpret the key climate aspects of your technology, we assign each process item two labels to serve as high level indicators. Your most significant climate impactThe "Score" evaluates processes based on comparative impact: Aligned signifies measurable emission reductions compared to the benchmark; Potential suggests possible alignment pending further verification; Negative denotes additional emissions; Rebound identifies emissions that would have otherwise not occurred with the benchmark; and None represents qualitative assessments. The "Priority" label ranks processes by importance: High indicates critical processes essential for achieving key sustainability objectives, warranting immediate attention; Medium represents processes contributing to the impact profile that require attention but lack urgency; and Low applies to supplementary processes with less immediate impact or those already aligned, allowing deferred action until higher-priority tasks are addressed. Impact factor # Process item Scope Score Priority Impact AnalysisFunctional unit profileThis graph represents the aggregation of all the aforementioned emission factors with respect to the defined functional unit. By selecting a benchmark, the corresponding avoided emissions will also be displayed on the graph. This enables you to see the difference in the emission profile that this climate solution has to the incumbent technology. There is also an effect filter to identify which impact factors only occur once and which recur multiple times, usually throughout the lifetime use of the product or service. You can click the process labels in the legend to hide and show different elements to reveal further insights.

ProjectionsHow to read this section

Scenario 1: Planned impact (business projections)The aggregated impact scenario in the Nosh report reflects the planned production of the company's protein, considering factors like resource consumption, emissions, and waste generation. It highlights the overall sustainability benefits or challenges, compares them with traditional protein sources, and suggest pathways for reducing environmental impacts. This scenario aims to offer a holistic view of the product's life cycle, emphasizing key areas for improvement and potential for environmental savings. Benchmark 1: Conventional beef (per weight comparison)The main benchmark of this report is the production of conventional beef. It is compared on a 1:1 weight basis to NOSH's protein. The benchmark considers the lifecycle of beef production cradle-to-gate, however excludes farm building emissions due to the lack of reliable data. This benchmark is compared to the alternative protein of Nosh, revealing the differences in environmental impacts. Scenario 1: Planned impact (business projections)The aggregated impact scenario in the Nosh report reflects the planned production of the company's protein, considering factors like resource consumption, emissions, and waste generation. It highlights the overall sustainability benefits or challenges, compares them with traditional protein sources, and suggest pathways for reducing environmental impacts. This scenario aims to offer a holistic view of the product's life cycle, emphasizing key areas for improvement and potential for environmental savings. Benchmark 2: Conventional beef (protein content comparison)This benchmark compares the emissions of NOSH's product on a protein content basis. As the company's product has 1/3 of the protein of conventional beef, around 3 times the amount of NOSH's product is required for the same amount of protein. Scenario 2: Per kg of product (single unit impact, year-by-year)The per kg scenario in the Nosh report quantifies environmental impacts associated with producing one kilogram of Nosh protein, detailing resource use, emissions, and energy consumption. It offers insights into the efficiency and sustainability of the production process, highlighting areas for optimization. This scenario helps stakeholders understand the environmental footprint of Nosh protein on a granular level, guiding efforts to minimize impacts and enhance the product's sustainability profile. Benchmark 1: Conventional beef (per weight comparison)The main benchmark of this report is the production of conventional beef. It is compared on a 1:1 weight basis to NOSH's protein. The benchmark considers the lifecycle of beef production cradle-to-gate, however excludes farm building emissions due to the lack of reliable data. This benchmark is compared to the alternative protein of Nosh, revealing the differences in environmental impacts. Scenario 2: Per kg of product (single unit impact, year-by-year)The per kg scenario in the Nosh report quantifies environmental impacts associated with producing one kilogram of Nosh protein, detailing resource use, emissions, and energy consumption. It offers insights into the efficiency and sustainability of the production process, highlighting areas for optimization. This scenario helps stakeholders understand the environmental footprint of Nosh protein on a granular level, guiding efforts to minimize impacts and enhance the product's sustainability profile. Benchmark 2: Conventional beef (protein content comparison)This benchmark compares the emissions of NOSH's product on a protein content basis. As the company's product has 1/3 of the protein of conventional beef, around 3 times the amount of NOSH's product is required for the same amount of protein. Scenario 3: Per ton of product (single unit impact, year-by-year)The per ton scenario in the Nosh report quantifies environmental impacts associated with producing one kilogram of Nosh protein, detailing resource use, emissions, and energy consumption. It offers insights into the efficiency and sustainability of the production process, highlighting areas for optimization. This scenario helps stakeholders understand the environmental footprint of Nosh protein on a granular level, guiding efforts to minimize impacts and enhance the product's sustainability profile. Benchmark 1: Conventional beef (per weight comparison)The main benchmark of this report is the production of conventional beef. It is compared on a 1:1 weight basis to NOSH's protein. The benchmark considers the lifecycle of beef production cradle-to-gate, however excludes farm building emissions due to the lack of reliable data. This benchmark is compared to the alternative protein of Nosh, revealing the differences in environmental impacts. Scenario 3: Per ton of product (single unit impact, year-by-year)The per ton scenario in the Nosh report quantifies environmental impacts associated with producing one kilogram of Nosh protein, detailing resource use, emissions, and energy consumption. It offers insights into the efficiency and sustainability of the production process, highlighting areas for optimization. This scenario helps stakeholders understand the environmental footprint of Nosh protein on a granular level, guiding efforts to minimize impacts and enhance the product's sustainability profile. Benchmark 2: Conventional beef (protein content comparison)This benchmark compares the emissions of NOSH's product on a protein content basis. As the company's product has 1/3 of the protein of conventional beef, around 3 times the amount of NOSH's product is required for the same amount of protein. |

ClimatePoint Funding the Future ClimatePoint AS Universitetsgata 12, 0157 Oslo |

ClimatePoint AS, Universitetsgata 12, 0157 Oslo Follow us on X | Follow us on LinkedIn |